Mistras PHAT Scan©

In-service storage tank inspection

PHAT Scan© is a NDT examination technique used for non-invasive and in-service inspection of the internal shell-to-bottom connection (corner weld) on above ground storage tanks and/or the annular critical weld region of the annular plate.

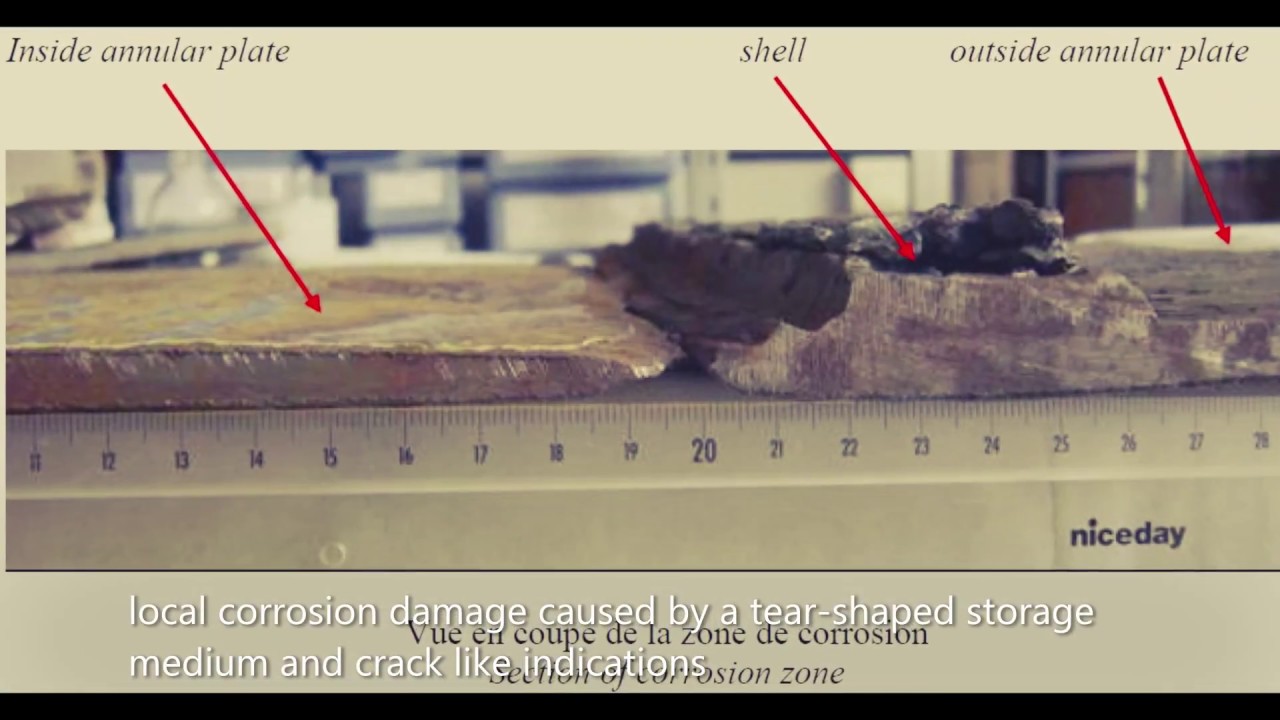

With PHAT Scan © local corrosion damage caused by a tear-shaped storage medium and crack like indications, in which the crack orientation perpendicular to the vessel wall is due to low cyclic fatigue, can be recorded. On-stream / non-intrusive inspection (NII) technology.

| Specification Title | Specification Description |

|---|---|

|

Application

|

Above ground storage tanks.

|

|

Inspection

|

The internal shell-to-bottom connection (corner weld) and/or the annular critical weld region of the annular plate

|

|

In-service inspection possible

|

Yes, in-service inspection available with PHAT Scan©

|

|

Accuracy

|

Accuracy of the remaining annular plate thickness measurement is 10%. Crack-like indications, pit shaped corrosion and pitting can be detected and sized from an indication depth/height of ± 1,5 mm (0,06”)

|

|

Temperature

|

From 5°C till 50°C.

|

|

Areas of Application

|

Shell and annular plates within the storage tanks.

|

|

Repeatability

|

Measurements from the past can be compared with current measurement data.

|

|

Compliance

|

EEMUA 159 / API 653

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 5 deployment references.

Last Deployment Year