ROVAR-01 and ROVAR-20

Remotely Operated Vehicle for Asset Recovery utilising controllable buoyancy

What is ROVAR

- Patented cryogenic ‘ROVAR’ technology (“Remotely Operated Vehicle for Assets Recovery”)

- Variable Buoyancy System which exploits the properties of cryogenics for controlled subsea lifting and handling operations.

- Precise descent and ascent is achieved by vapourising liquid nitrogen to displace seawater from buoyancy caissons

- Key components

- Liquid Nitrogen dewar

- Gasification system including actuators and cryogenic valves to provide heat exchange and flow control of gas into the caissons

- Actuated relief (dump) valves to retain gas within caissons, and to release it from them

- Primary sensors – depth / pressure gauge, sonar (distance from seabed), load cells

- Advanced control system – controls flow of gas into and out of caissons which adjusts buoyancy dependent on depth, load, rate of ascent or descent required

- Data and power umbilical to control console

- In-built thrusters control lateral motion with standard or bespoke toolsets and grabs for handling

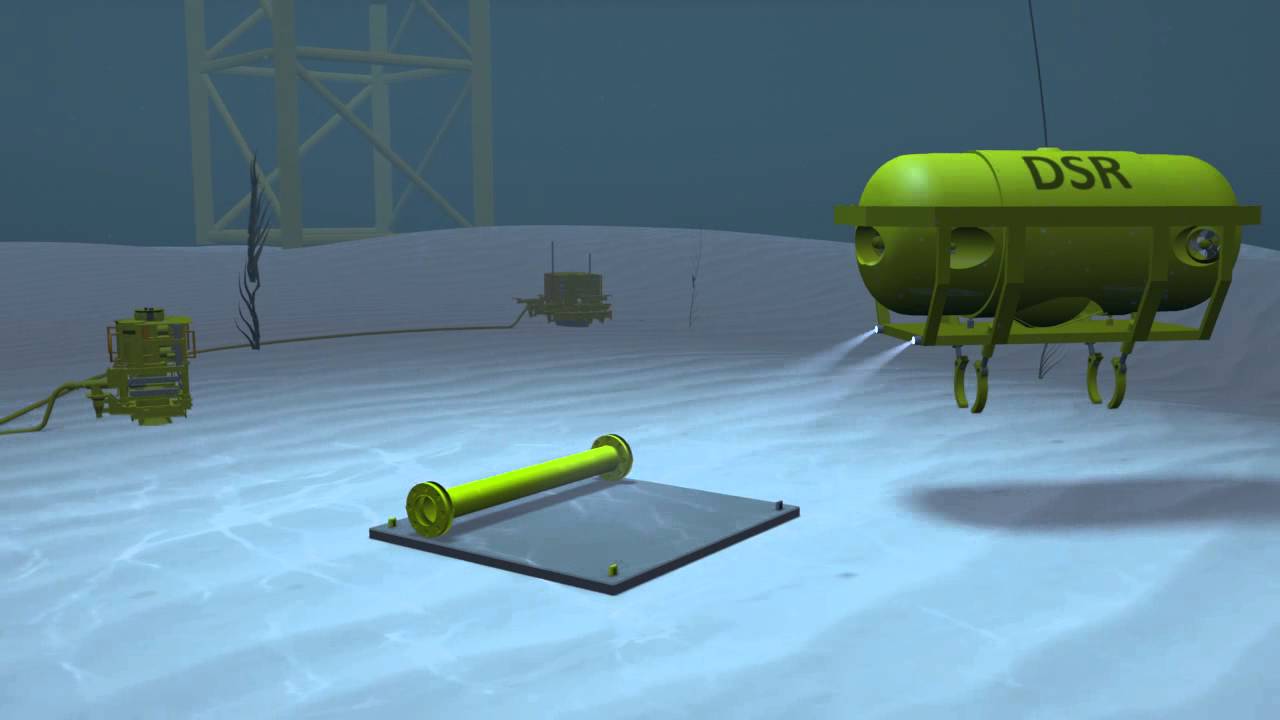

ROVAR is a fully scalable technology and can be adapted to address different lifting and handling challenges subsea. Our standard unitary systems are ROVAR-01 and ROVAR-20 which can also be deployed in multiplex modes for manoeuvring of much heavier or more complex loads requiring multiple lifting points due to shape, uneven load distribution etc.

ROVAR-01 has a 1-Tonne lift capability and can be used for debris and UXO removal from restricted areas. It has a footprint of approximately 2.7m length and 1.1m cross-section.

ROVAR-20 has a 20-Tonne lift capability and can be used for more substantial offshore handling and recovery as an underwater crane or 'seabed forklift'. It has a footprint of between 4m and 6.6m long with a cross-section of 2.7m.

ROVAR offers:

o Lift repeatability – the inherent design provides capability for repetitive tasks whilst remaining in-situ and minimising support vessel time

o Practical operating depths - down to 2,000 msw

| Specification Title | Specification Description |

|---|---|

|

Caissons

|

Open bottomed GRP buoyancy caissons (min 2 per system) which can be independently controlled

|

|

Liquid Nitrogen Dewar

|

Pressure vessel design comprising stainless steel inner and carbon fibre outer, with insulation in between.

|

|

Gasification system

|

Pressure build circuit in dewar, actuated cryogenic flow valves, heat exchange piping exposed to sea water

|

|

Load bearing 'rings'

|

Carbon fibre load rings with load cells attached to selected grab mechanism

|

|

Sensors and ancillary equipment

|

Depth/pressure, sonar (distance to seabed and other obstructions, gyros, lights, cameras, navigation

|

|

Thrusters

|

Vectored thrusters to enable neutrally buoyant system to travel in horizontal plane

|

|

Actuated relief valves

|

Within caisson to allow controlled retention or release of nitrogen, thereby varying buoyancy levels

|

|

Control system

|

Hardware and software, power and data umbilical, to remotely control lifting operations from topside console

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[6/9]