Cumulus Quality Management System (QMS)

Optimize quality assurance for your facility and track real-time work progress with our award-winning QMS

Rework is killing project margins, representing a staggering 12% of total project costs. Cumulus QMS makes it easy to eliminate tedious paperwork and costly mistakes. From bolted joints and pressure testing to solar panel installations and tank car maintenance, the Cumulus QMS digitize any work procedure in just a few clicks.

Cumulus empowers users with a single pane view of exactly what is happening in the field, in real time. With our QMS, you’ll always know who did the work, when they did it, and—most importantly—if it was done correctly. All on one dashboard.

How It Works

1. Digitize Work Procedures. Convert existing standard operating procedures into digital workflows within seconds. Cumulus Pro can also create a new procedure for you based on large datasets of industry best practices, or translate workflows into any language.

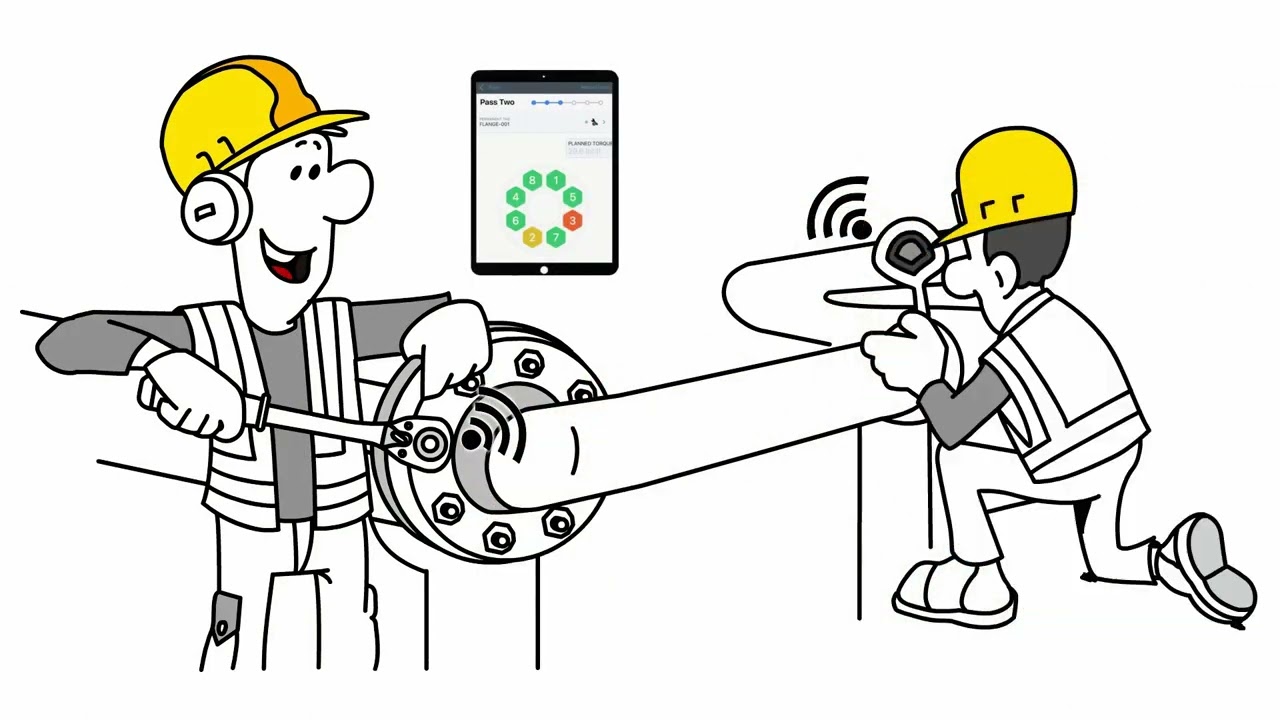

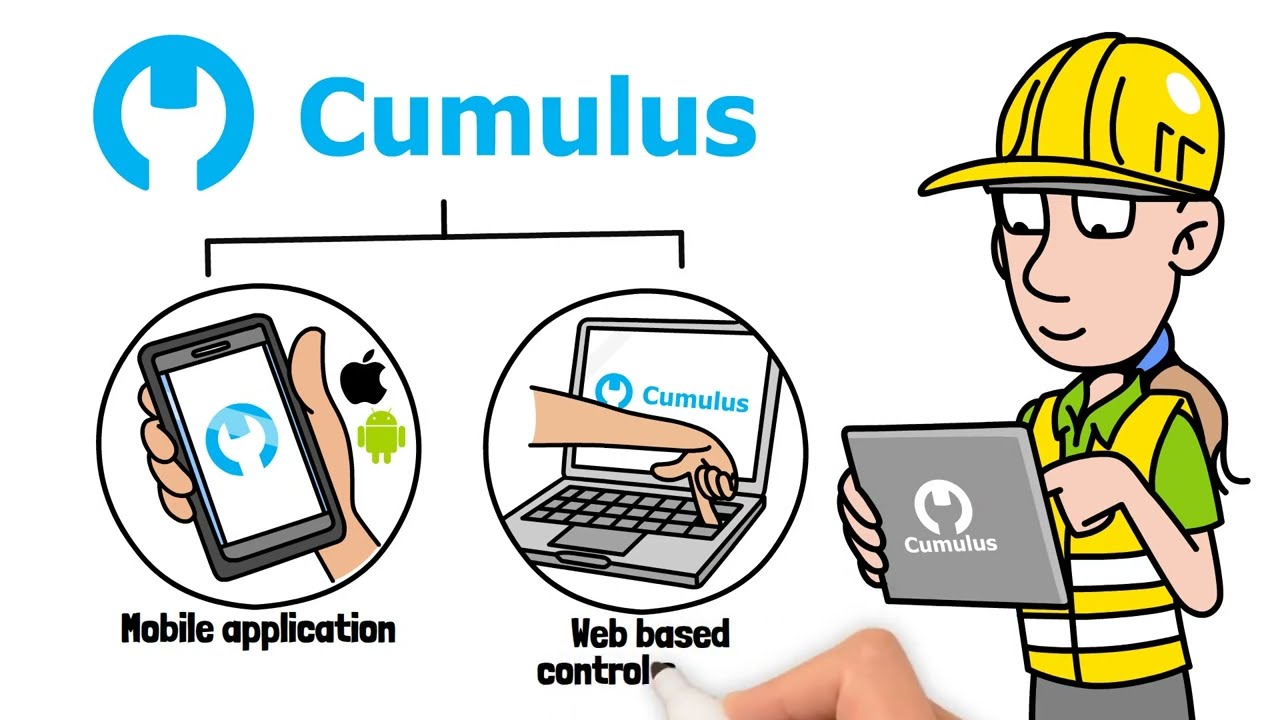

2. Connect Your Workforce. Share workflows with colleagues, who can immediately start using your workflows in the field via any mobile or tablet device to ensure process adherence. Each workflow automatically requires quality data to ensure process adherence.

3. Confirm Work Quality. Validate work quality and progress via Cumulus Pro’s traceable history of work activities. It automatically generates comprehensive work completion reports on who did the work, when they did it, and most importantly, if it was done correctly.

Product Features

- Compatible with Bluetooth tools: Connect with Bluetooth tools, such as torque wrenches and pressure gauges, to capture granular quality data

- Worker-Oriented Mobile App: Intuitive access to essential work information, interactive tools, and data entry features

- Powerful AI-Assisted Workflow Builder: Streamline process management for any work activity, from inspections to installations.

- Exportable Work Completion History: Record a detailed history of all completed work for documentation and analysis purposes.

- PDF Drawings in the Field Mobile App: Access PDF drawings directly on the mobile app for easier reference and implementation.

- Project Analytics Dashboard: Track key performance indicators (KPIs) like productivity, quality, and safety in real-time.

Prevent rework and upskill your workforce with the Cumulus Quality Management System.

| Specification Title | Specification Description |

|---|---|

|

Smart Tool Connectivity

|

Connect with compatible Bluetooth-enabled wrenches, such as Snap-on and Hytorc, to verify proper manual torquing. Works with Wika and Additel hydraulic pressure gauges to verify proper hydraulic torquing, tensioning and pressure testing. Works with Hytorc electric torque devices.

|

|

Works In Offline Environments

|

Work with or without wireless connectivity in the field

|

|

Single Sign On (SSO)

|

Single-sign-on integration with your company's identity provider, SOC 2 Type 2 Report Available

|

|

iOS and Android Compatible

|

Field-ready application can work on both iOS and Android mobile and tablet devices

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 12 deployment references.

Last Deployment Year