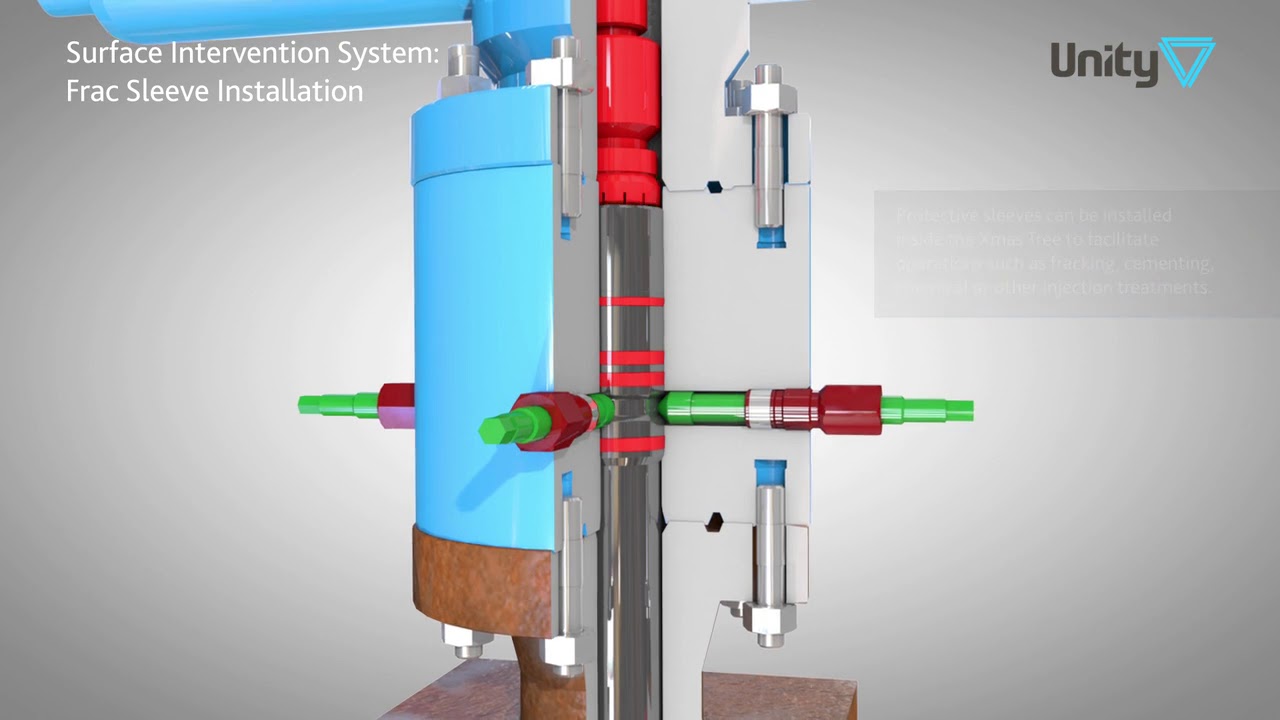

Surface Intervention System (SIS)

Well Integrity. Done Well.

The first and only system dedicated to near-surface intervention. Delivers a fast, efficient solution onshore or offshore. Multiple operations are performed consecutively at the wellsite. Powerful push and pull capability. Reduced HSE risk, deck space and personnel requirement. Life-of-well support from production optimisation to pre-abandonment. Large cost savings compared to wireline and coiled tubing by reducing personnel, mobilisation costs, and rig up time. Compact system dedicated to shallow intervention work in the tree to tubing hanger range. Fast to deploy using existing Unity wellhead technicians, further reducing headcount, especially when combined with ongoing maintenance

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Plugs - 70,000 lbs push and 40,000 lbs pull | Frac Sleeve deployment | Inspection access to live well.

|

|

OPEX

|

OPEX reduced significantly over traditional methods. A typical wellhead repair requiring plugs to be set can be achieved in 3 shifts by 2 wellhead technicians.

|

|

Optimisation

|

The SIS optimises intervention work by providing a compact footprint, reduction in planned operation time, reduced POB and the system is operated by our wellhead technicians who will also conduct the repair work.

|

|

Compatibility

|

The SIS is compatible as a direct replacement for wireline and coiled tubing operations when conducting shallow intervention work.

|

|

Runtime

|

A typical operation to rig up, run in hole, and set a plug can take as little as 4 hours.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 16 deployment references.

Last Deployment Year