Sealant for DHSV Hydraulic Leak Repairs

Robust isolation for DHSV system leaks

KCI recognised the need for a new approach to repairing leaks in Control Lines.

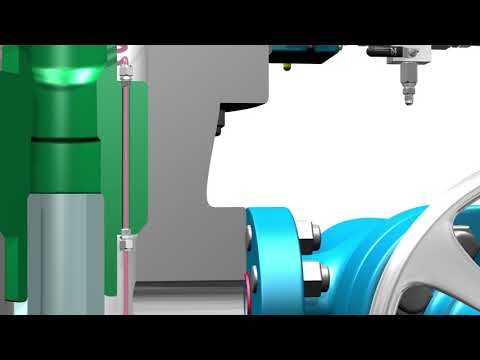

IG-FP was formulated to isolate leaks in Down Hole Safety Valve (DHSV) Control Line Compression fittings where the hydraulic fluid is leaking out of the system.

Leaking Control Lines can create issues by losing control fluid to the Well bore, the A-Annulus or building up hydraulic pressure in the Tubing Hanger Void.

The Well may have to be shut in and taken offline if hydraulic leaks are excessive or if the DHSV cannot be kept open.

By simply deploying IG-FP the leaks in the system will be stopped while maintaining full operational control of the DHSV. IG-FP remains soft and does not cure or change viscosity.

| Specification Title | Specification Description |

|---|---|

|

Chemical characteristics

|

IG-FP is a slick, pre-cured, non-setting gel with micro sealing elements mixed throughout

|

|

Temperature range

|

-50 to 175°C

|

|

Pressure rating

|

10,000 psi

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]