ROSEN Inspection of Corrosion under Pipe Supports

Highly sensitive and rapid in-service and non-intrusive feature detection for non-accessible areas

Corrosion at inaccessible areas is one of the leading causes of topside process piping failure. ROSEN delivers in-field inspection services that leverage EMAT technology. It can be used for difficult-to-reach areas such as CUPS, pipe supports, pipes in walls, partially buried pipelines, and pipes that are positioned in close proximity to each other, such as pipe racks. Other applications include e.g. coated pipes, areas next to supports, buried pipes as well as pressure vessels and tank shells.

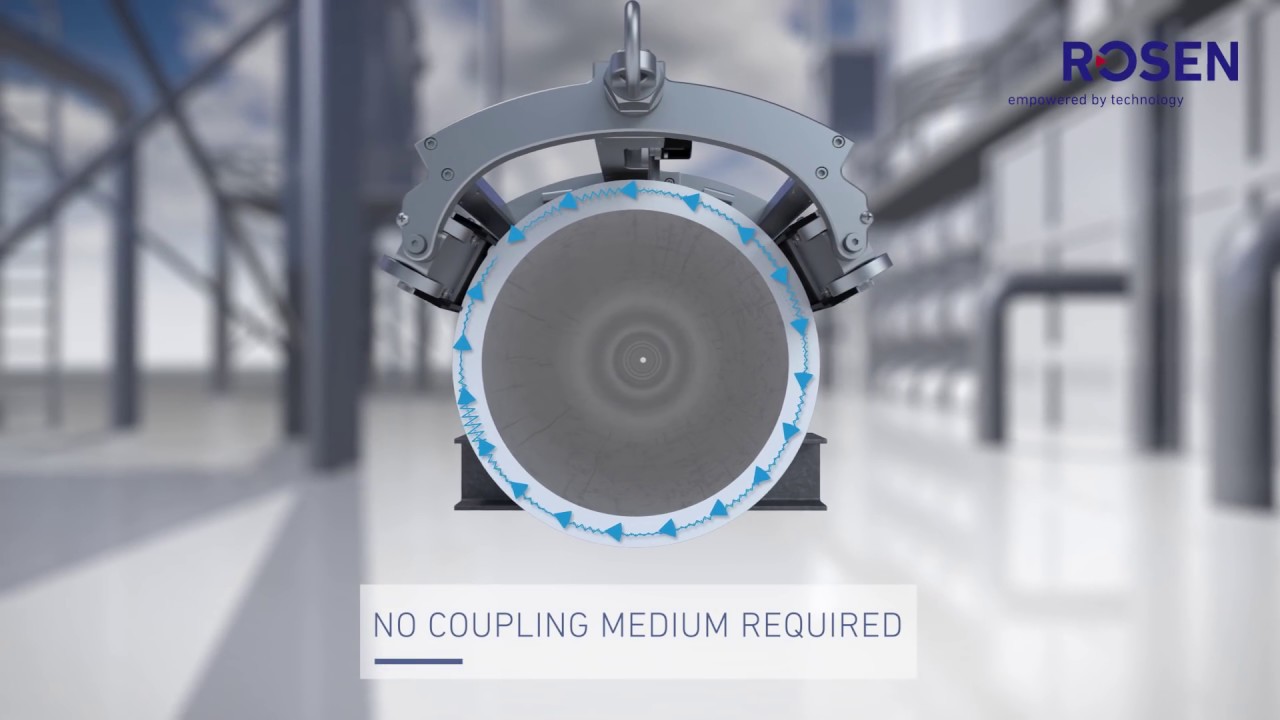

Measurement principle:

- EMAT lamb wave inspection in circumference and axial direction

- Detection and sizing of pit like indications and locate wall thinning

Key features for inspecting corrosion at pipe supports::

- Non-intrusive inspection (NII) method: Ability to inspect supports in service, without lifting.

- Highly sensitive feature detection

- Requires no special preparation and permits rapid screening

- Data is captured, stored and reported.

- Reports are automatically generated and the scans provide clear images of individual features and precise indication of position and dimensions

| Specification Title | Specification Description |

|---|---|

|

Accuracy

|

+/- 15% Wall thickness standard

|

|

Areas of Application

|

Above ground, non-insulated piping; Refineries, Terminals (jetties)

|

|

ATEX certified

|

No

|

|

Capabilities

|

Detection and quantification of pipe support corrosion; Various pipe support configurations

|

|

Certifications / licences

|

HOIS validated

|

|

Compliance

|

API 570

|

|

In-service inspection possible

|

Yes

|

|

Inspection

|

Piping 4 inch and larger; Wall thickness up to 15mm

|

|

Temperature

|

-20C till +100C standard

|

Reviews (1)

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year