Quickflange™ Weldless Connectors

Permanent gas tight flange-to-pipe connections without welding

For almost 20 years, our patented Quickflange™ technology has built up a proven track record as a leading provider in cold work solutions, offering clients a permanent repair option for improving pipeline integrity and flow assurance eliminating the need for welding or hot work.

With an extensive range, Quickflange™ is a safe, cost-effective and efficient solution generating up to 80% time saving over traditional welding.

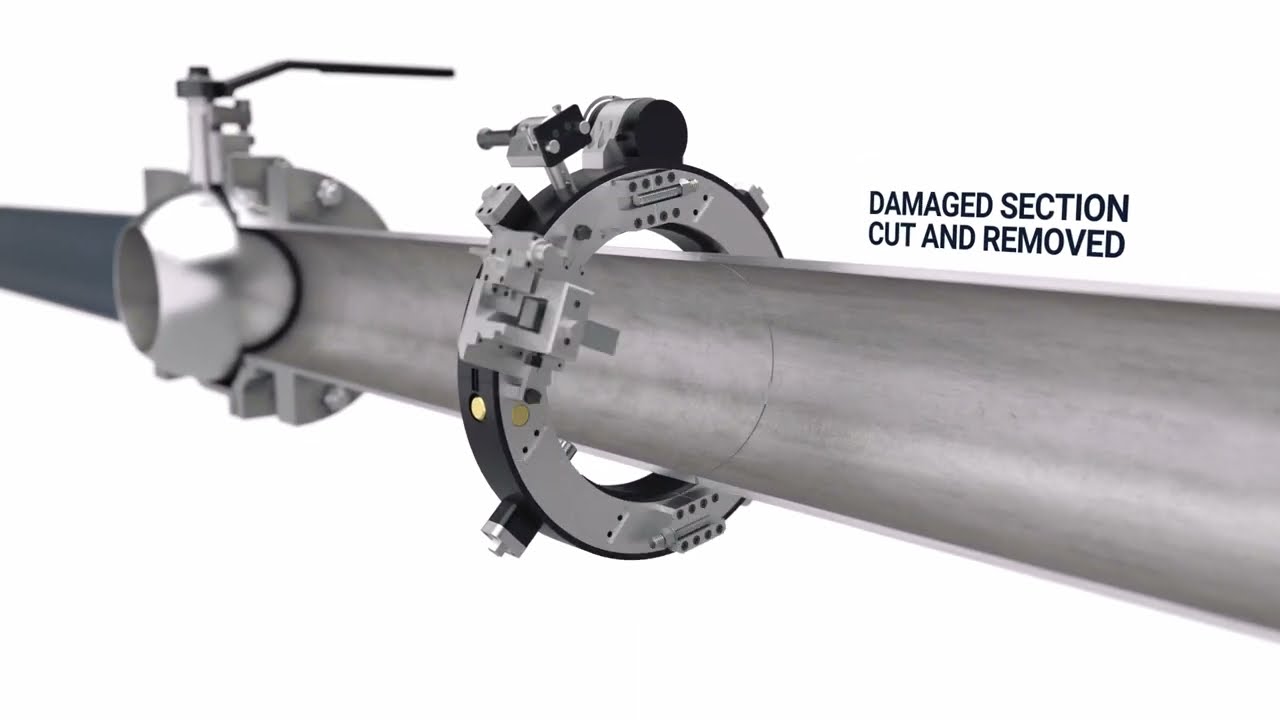

By combining our Quickflange™ connector with with our bespoke Quickflange activation tool, the process of installing a Quickflange weldless connector is both quick and easy. Once the line is isolated a straight cut is crucial to ensure the Quickflange™ sits flush to the pipe edge. The hydraulic tool is aligned into the pipe and activated to the required pressure. During this process, the cone of the tool quickly extends allowing the segments to flare swaging the pipe into the pre-machined grooves of the Quickflange connector. The tooling is then reversed concluding the installation creating the permanent gas tight seal.

| Specification Title | Specification Description |

|---|---|

|

Accuracy

|

Highly accurate compared to welded connections as the connection is based on groove technology allowing for more accurate cutting and replacement of spool sections.

|

|

Asset life extension

|

Quickflange is extensively used to repair or replace pipelines both onshore and offshore from sizes ¾” to 14”.

|

|

Compliance

|

DNV and ABS Type Approved.

|

|

Cost

|

Cost effective solution | Reduced manpower | Higly efficient | Fast turnarounds with “off the shelf” product available.

|

|

Lifespan

|

Permanent solution for improving pipeline integrity and flow assurance.

|

|

Pressure class

|

150# to 2500#

|

|

Repairs

|

Quickflange™ can be used as means to repair damaged or corroded pipework as well as modification or construction of new pipework through to decommissioning of redundant lines.

|

|

Repeatability

|

20,000 installations performed worldwide over the last 2 decades.

|

|

Safety

|

No hot work, emissions or spark potential.

|

|

Speed

|

80% minimum time saving over welding.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[7/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 9 deployment references.

Last Deployment Year