Portable Vertical Lay System (PVLS)

Road-transportable system for deployment and decommissioning of flexible products.

The award-winning MDL PVLS is a portable vertical lay system for the deployment and decommissioning of flexible products such as cables and subsea umbilicals, risers and flowlines.

The innovation facilitates the transit of flexible products from on-deck carousels or reel drive systems to a vertical orientation so that they can be installed over the side, stern or through the moon pool of a vessel. The vertical orientation ensures that the product does not experience bending while under high tension during installation, minimising the risk of damage to the product.

A portable vertical lay system allows for these handling operations to be carried out from any low-cost vessel, readily available at any location around the world, converting it from a standard offshore support vessel into a dedicated flex-lay solution for the duration of the project.

The use of a locally available vessel, rather than bringing a specialist installation vessel from another geographical location, combined with the smaller tonnage of the opportunity vessel, help reduce the CO2 footprint of the project. These green efficiencies are extended when more product can be carried on board, thanks to the integrated and compact design of the MDL PVLS - reducing the number of port calls required to complete installations of longer lengths of product.

The ability to convert a bare back deck into a vertical lay solution, enables completion of projects that may otherwise be delayed due to the lack of a dedicated construction vessel available in region in the required installation window - helping the operators meet their production targets linked to the tie-back scopes.

With over 20+ track record in innovative design and manufacture of lifting and pulling equipment for the marine markets, MDL is an expert in delivering bespoke equipment that works from the get-go. The technology is developed fully in-house, including intuitive control systems that allow safe integration of systems for efficient operations.

| Specification Title | Specification Description |

|---|---|

|

Lay Spread Type

|

Portable Vertical Lay System

|

|

Max Pipe Tension

|

75Te (dynamic load)

|

|

Max Hang-off Clamp Tension

|

80Te (dynamic load)

|

|

Design Life

|

25 years

|

|

Design Temperature

|

Operational: -10ºC +50ºC; Survival: -20ºC +65ºC

|

|

Low Tension MBR Top

|

4m top chute (10Te)

|

|

Min Pipe Diameter

|

50mm OD

|

|

Max Pipe Diameter

|

650mm OD

|

|

Movable Top Chute

|

±15º

|

|

PVLS Geometry Dimensions (approx. depending on configuration)

|

12m x 9.6m x 22.7m (LxBxH)

|

|

Weight (excl. tensioner)

|

167Te

|

|

Hang-off to Tensioner Clearance

|

6.6m

|

|

Moonpool Door to Tensioner Clearance

|

7.4m

|

|

Work platform deck area

|

27m²

|

|

Work Platform Deck Capacity

|

1Te/m²

|

|

Work Platform Opening

|

3m

|

|

Lifting Equipment

|

All items supplied with dedicated rigging rated for onshore lifts

|

|

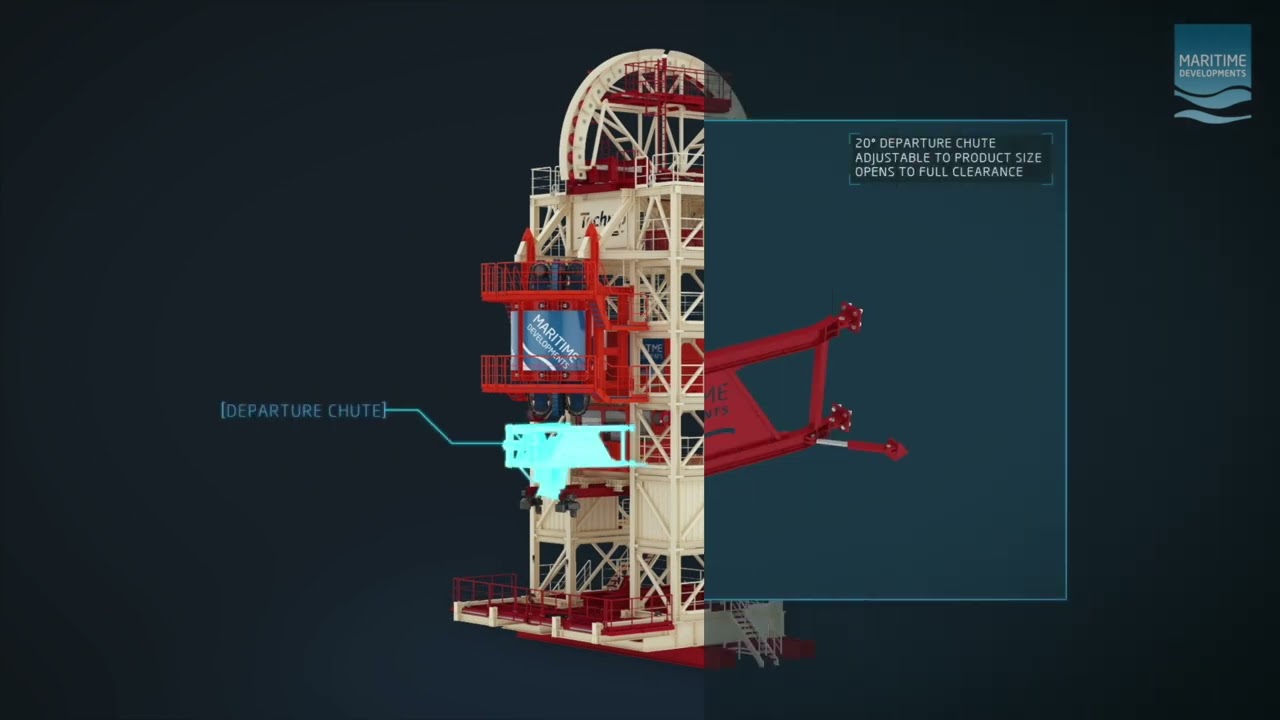

Departure Chute (option)

|

20º off-lead; 5º fore and aft

|

|

Power Requirements (VLS only)

|

1x 55kW; 1x 75kW

|

|

Design Appraisal

|

Design appraised in accordance with DNV standards

|

|

Assumed Conditions

|

Humidity: up to 100%; Atmosphere: marine/high salinity

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 7 deployment references.

Last Deployment Year