Pipeline Digital Twin Platform

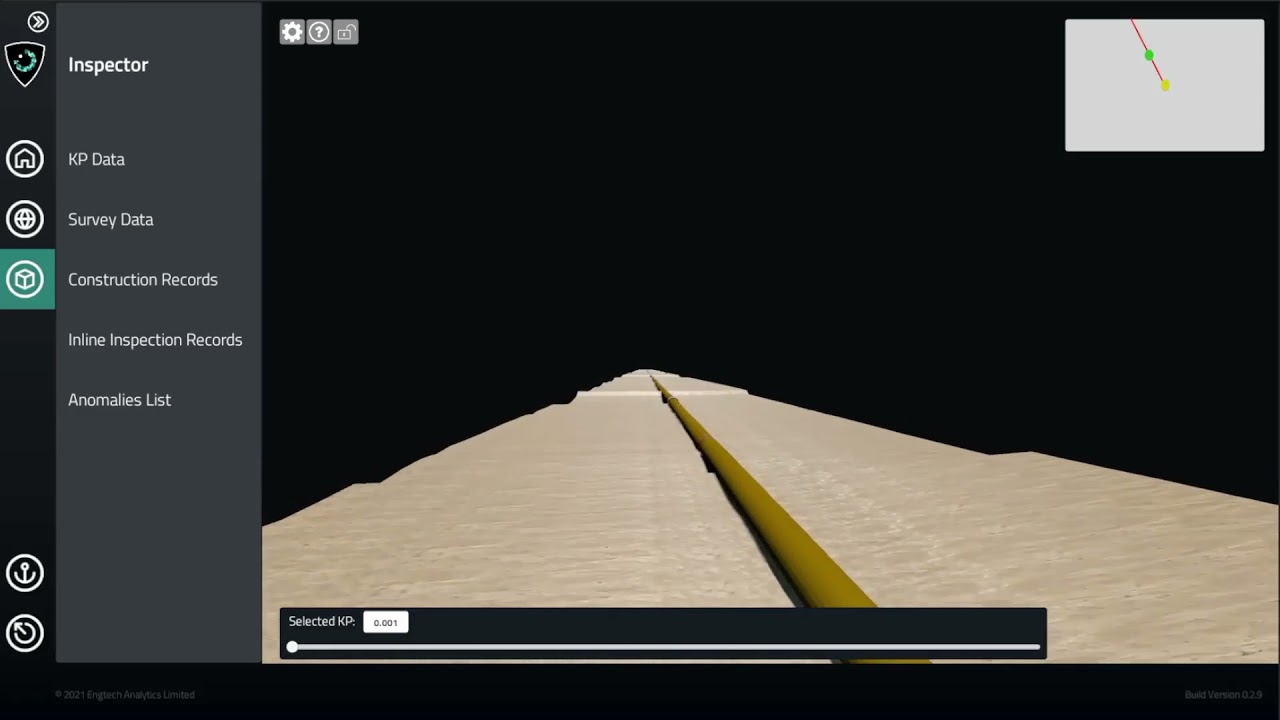

Provide Context to Pipeline Data

A pipeline Digital Twin web platform, that organizes links and provides context to pipeline data. By organizing and linking data on the platform, integrity assessments are automated using real time data. No need to wait months for an assessment only to be surprised by a result. By using all available data and automating engineering assessments our system performs all levels of analysis when it is required. The system is based on efficiency and scalability as an example analysis of an anomaly such as a free span exceeding allowable length cant take up to 1 week per anomaly, our system can analyse this anomaly in minutes with better results as we take into account all available datasets reducing uncertainties , risks and conservatism. In a trial our system reduced the offshore intervention requirements by 90%.

| Specification Title | Specification Description |

|---|---|

|

Organized Data Storage - Online Portal

|

All your pipeline data is linked to location and time making it easily accessible by human and machine. Allows for creation of engineering apps and makes data transfer between supplies simple. Empowers pipeline operators with control over all there data.

|

|

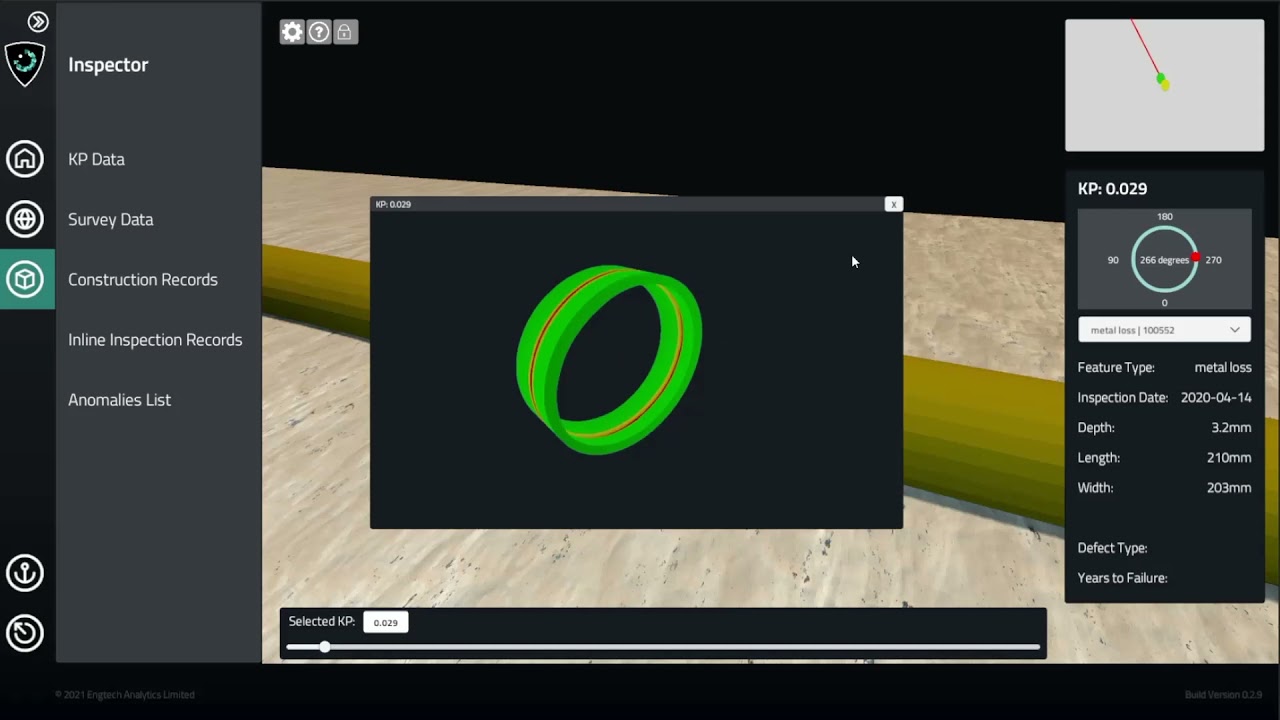

Automated Corrosion Engineering Assessments

|

Automated engineering assessment for corrosion defect. FEA modelling automated if defect requires this level of analysis. Utilizing all available data we guarantee there will be less anomalous defects.

|

|

Automated Freespan Engineering Assessments

|

Automated engineering assessments for pipe spans. FEA modelling automated if span requires this level of analysis. Utilizing all available data we guarantee less offshore interventions on your assets.

|

|

Construction Validation Module

|

Capturing manufacturing and construction data at its time of creation allows for a rapid validation process. Data handover between contractors and suppliers is efficiently managed from one source of truth.

|

|

Dry Pre-commisioning Module

|

By taking a data driven approach and utilizing all available data sets our dry pre commissioning module can be used to validate the introduction of hydrocarbons into flowlines without a hydrotest.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year