MySep Engine

Accurate separation modelling in leading process simulators

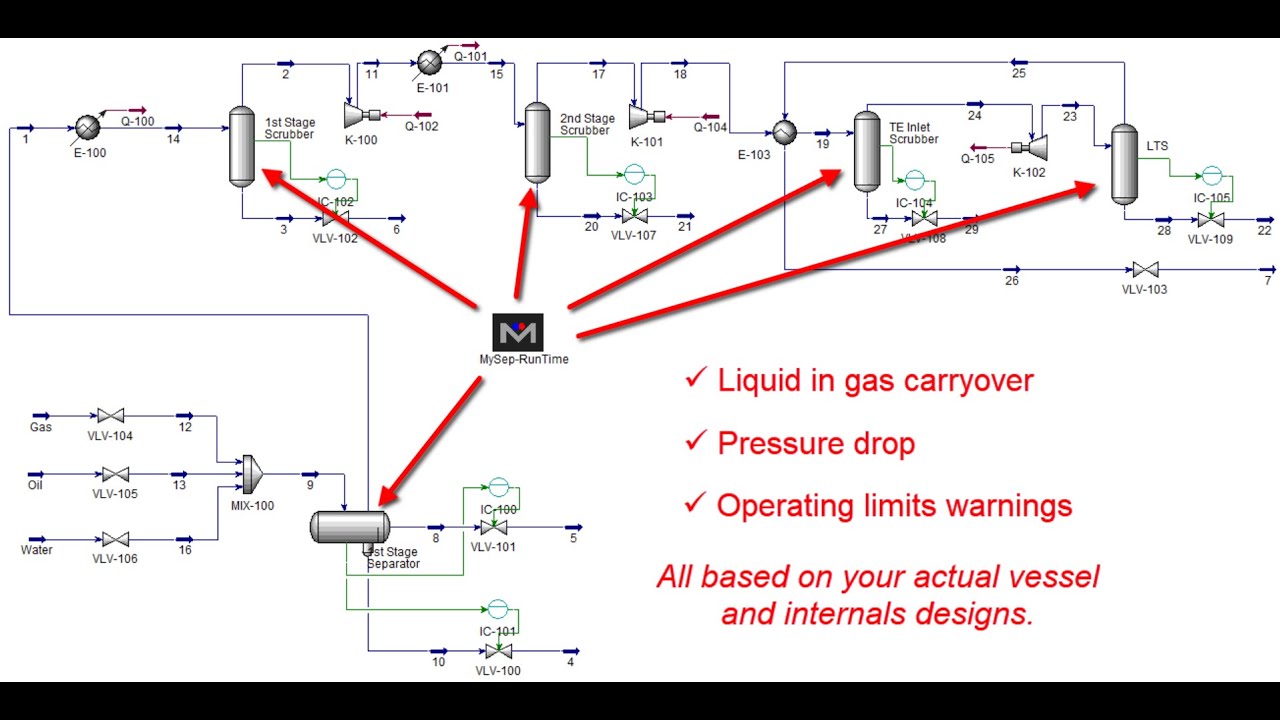

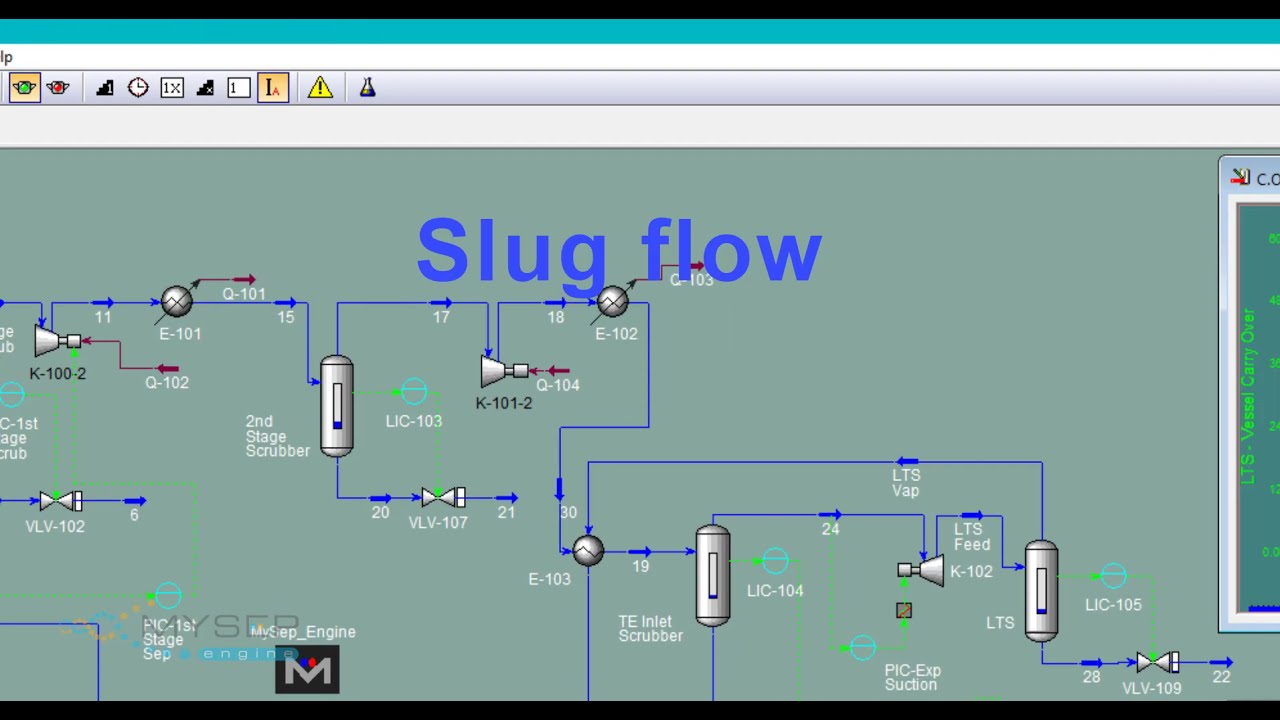

MySep Engine™ gives users of leading process simulators access to MySep separator modelling rigour for vapour-liquid separation, within their dynamic or steady state simulations. This brings much more accurate overall process modelling in applications where carry-over will have significant impact on heat and material balances.

Carry over of liquids with vapour can have a significant impact accuracy of material and heat balances in process simulations. The MySep Engine module embeds an accurate representation of gas-liquid separation behaviour inside a dynamic or steady-state process model. In addition to physically based representation of pressure drop and carry-over performance MySep’s practical warnings indicate where operational limits are exceeded.

Case studies on production optimalisation, troubleshooting and digitalisation can be found on https://www.mysep.com/case-studies-and-downloads.

| Specification Title | Specification Description |

|---|---|

|

Industry

|

Used throughout the industry by End-users, operators and contractors

|

|

Areas of application

|

Conceptual design, FEED, Details design and throughout Operation (optimization, capacity increase, troubleshooting)

|

|

Process simulators

|

HYSYS® , UniSim® , DYNSIM® , K-Spice® , Petro-SIM® , Symmetry®

|

|

Simulation types

|

Steady state & Dynamic simulations

|

|

Vessel and internals configurations

|

Horizontal, Vertical, 2-phase, 3-phase. All configurations that can be modelled in MySep Studio

|

|

Calculations basis

|

Actual vessel geometry, inlet piping size and internals details. Vessel inlet process condition. Detailed performance calculations use same methodology as MySep Studio

|

|

Calculated data to simulator

|

Vessel HC liquid carryover rate, vessel water carryover rate, vessel pressure drop

|

|

Calculated data in simulator

|

K-values, Droplet size distributions ,Mist fractions, Carryover rates, Separation efficiencies

|

|

Warnings

|

Informational warnings on exceeding of alarm liquid levels, inlet momentums, K-values, etc. Critical warnings on exceeding shutdown liquid levels, insufficient drainage head, overloading of drain pipes, etc

|

|

Usage

|

Easy pairing of vessels in simulation with vessels in geometry file. Overview of vessel dimensions, internals types, level setpoints, etc of all vessels Display calculated parameters and warnings in strip charts (dynamic simulations)

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 8 deployment references.

Last Deployment Year