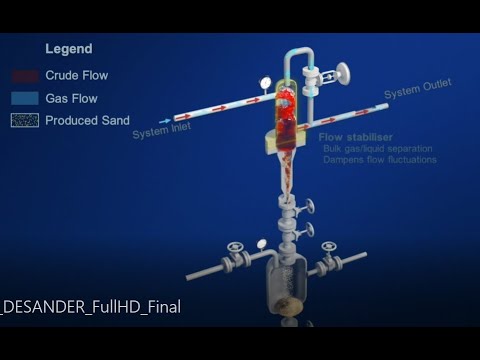

Multiphase Sand Separation System

A high efficiency cyclonic de-sander with integral flow stabilizer for multiphase oil and gas wells

Solids are undesirable during the production of oil and gas as it can lead to issues such as erosion of facilities, compromised safety and reduced production efficiencies. Existing sand removal methodologies are also inefficient due to the intricacies of multiphase flow, variations in production and frequent intervention by operators.

This patented technology has been jointly developed in collaboration with PETRONAS to mitigate these inherent issues in a cost effective manner that offers high flexibility for naturally varying flow regimes at full well streams. It can be deployed as a stand-alone wellhead desander unit or as a bulk desander unit for main production pipelines with better and consistent performance results than conventional desanders. It is exceptionally beneficial for facilities that experience slugging, pressure surges and varying production rates..

The technology was the winner of "Spotlight on New Technology" award in OTC Asia 2018.

| Specification Title | Specification Description |

|---|---|

|

Footprint

|

Flexible design based on capacity - Range from 5 tons to 20 tons

|

|

Intellectual Property

|

Internationally Patented Technology (International Application No.: PCT/IB2012/000128) filed in Australia, UAE, Malaysia, Indonesia, Thailand, and Vietnam.

|

|

Certification

|

Electronic parts are ATEX certified as explosion proof/Flame proof (Exd) or Intrinsically safe (Ex ia)

|

|

Hazardous Area Classification

|

Zone 0 and above

|

|

Capacity

|

Unlimited. Skid design can be adapted to any flowrate.

|

|

Validation

|

U-stamped pressure vessels. DOSH registered equipment. API relief system.

|

|

Automation

|

Standard design is fully automated via Allen Bradley unit control panel, yet it can be integrated with different systems.

|

|

Material of Construction

|

Ceramic cyclonic liners

|

|

Location

|

Fit for Wellhead Platform, Central Processing Platforms, FPSO, and Onshore terminals.

|

|

Recognition

|

'Spotlight Technology' Award winner in OTC Asia 2018.

|

|

Turndown

|

High tolerance for production turndown to 10%

|

|

Specialty Equipment

|

Optional acoustic sand sensors with an analyzer software

|

|

Efficiency

|

High sand removal efficiency targeting 20 microns and above

|

|

Pressure Rating

|

Flexible. Fit for 150# up to 2500#.

|

|

Sand Disposal

|

Dispose sand in a sand bag/drum to be transported to disposal site onshore

|

|

Auxiliary Systems

|

Optional sand washing package for dumping sand overboard.

|

|

Flexibility

|

Sand monitoring aspect can be qualitative or quantitative via real-time monitoring by acoustic sand sensors, or load cells.

|

|

Instrumentation

|

Digital by default. Can utilize either instrument air or instrument gas.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 3 deployment references.

Last Deployment Year