Valve Leak Monitoring - MIDAS Meter

Non-Invasive Valve Leak Detection, Quantification & Trending

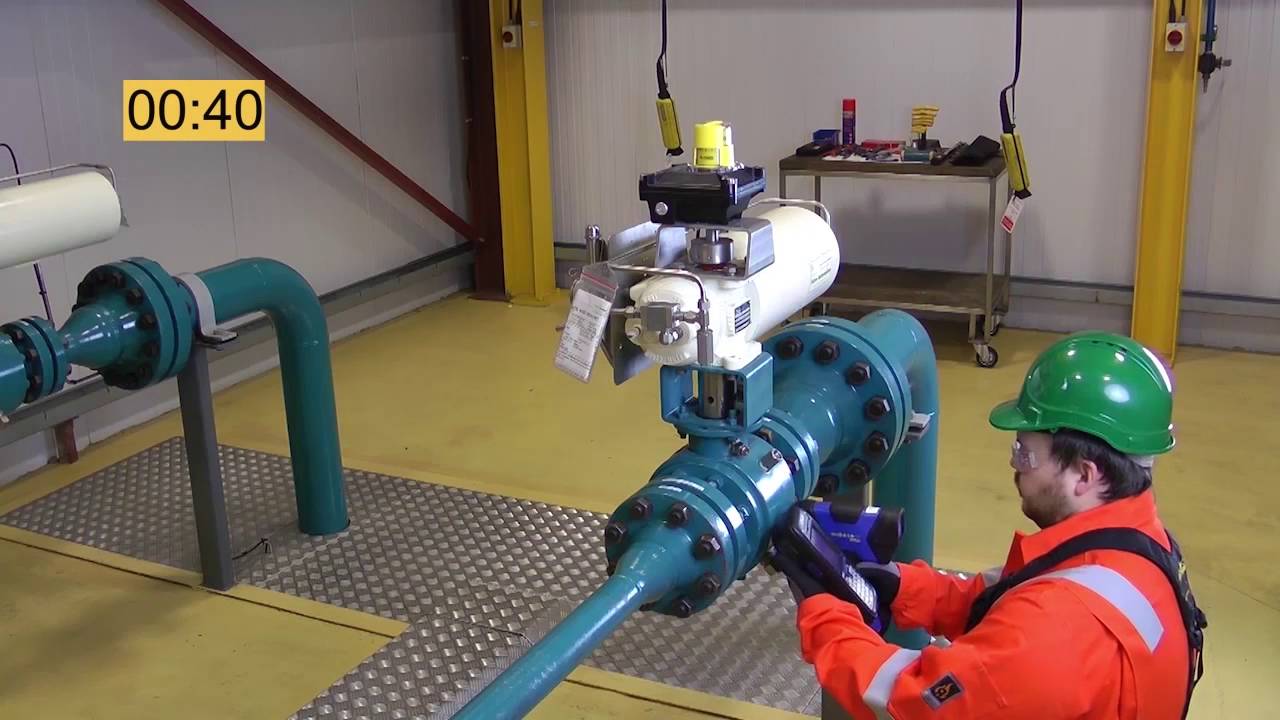

It is known that leaking valves represent a major environmental and safety risk and are a major source of lost profits. Find leaking valves quickly and easily with Score's MIDAS Meter® Acoustic Emission Leak Detector long before detection by conventional methods or instrumentation!

Completely portable and easy to use, the MIDAS Meter® uses an acoustic emission (AE) sensor which finds and quantifies through-valve leakages by examining the very high frequency noise a leaking fluid generates. This valve leak detection tool quickly finds leaking isolation valves, control valves, check valves, PSVs and steam taps, allowing personnel to benchmark valve performance during commissioning or operations and provides data storage, analysis and reporting in the field, via an instrinsically safe certified smartphone.

This state of the art valve condition and performance solution takes you from reactive to proactive maintenance, by engaging in condition based monitoring and predictive maintenance activities. MIDAS Meter® valve leak detection equipment therefore helps focus budget expenditure and actions on valves where maximum operational benefits can be delivered.

| Specification Title | Specification Description |

|---|---|

|

Acoustic Emissions Survey Technique

|

Technology researched, designed and manufactured in-house by Score Group

|

|

Leak Rate Calculator

|

Algorithm used to convert from dB to leak rate is proprietary to Score Group

|

|

Risk Based Inspection Calculator

|

Intelligent Valve Management approach to risk management is derived from Score Group's long market experience and expertise in delivering valve management contracts

|

|

Suitable for use on all valve types that are designed for isolating fluids flow (Liquids, Gas or Steam Service)

|

Ball, Gate, Globe, Check, Butterfly, PRV, PSV, Needle, Plug, Pinch, Diaphragm, Control, etc.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 23 deployment references.

Last Deployment Year