BISEP® Line Plugging

Hot Tap Installed Double Block and Bleed Isolation

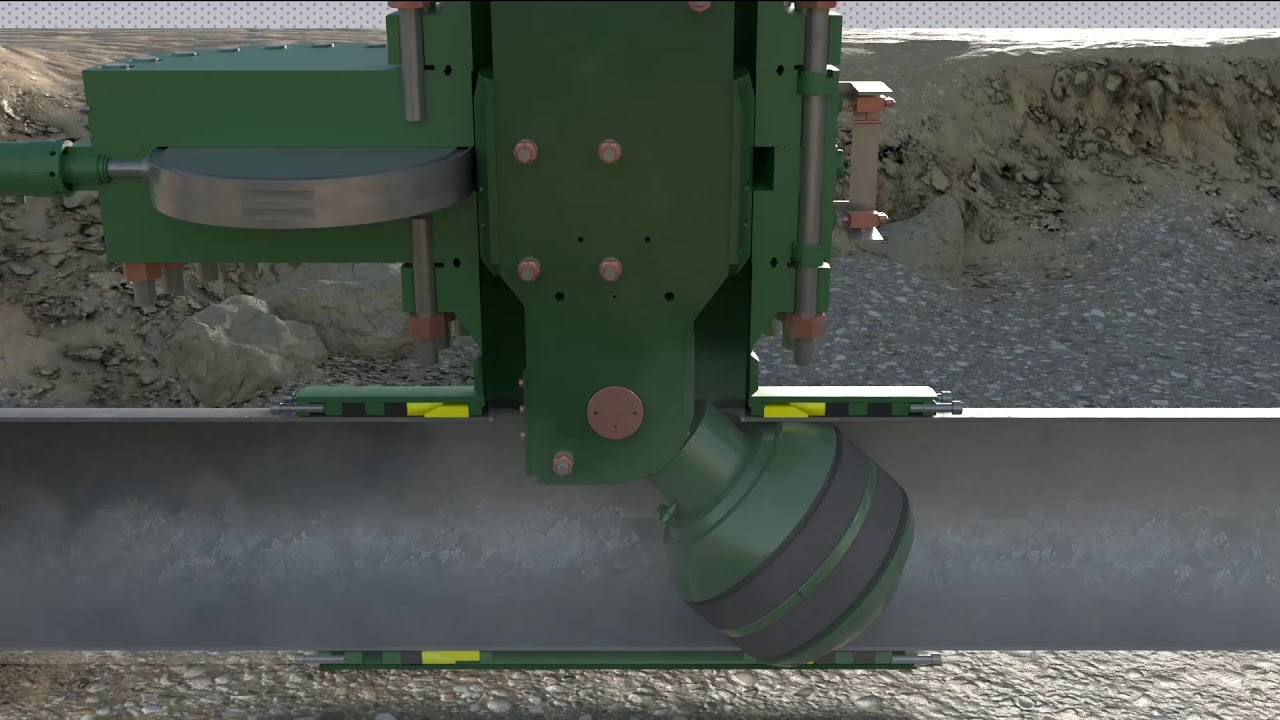

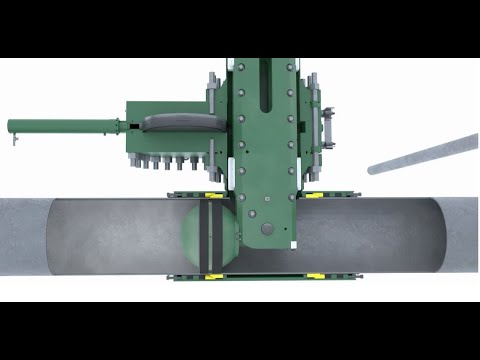

STATS BISEP® offers pipeline operators a solution using industry-leading technology for temporary line plugging. Achieved using patented and DNV Type Approved technology, the BISEP provides a fail-safe double block and bleed isolation deployed through a single full bore hot tap intervention, without the need for additional hot tapped bleed or vent ports. The BISEP offers significant safety advantages over traditional line stop technologies, with the hydraulically activated dual seals providing leak-tight isolation of live, pressurised pipelines.

This high integrity isolation is provided by a spherical dual seal plug which is hydraulically deployed into the pipeline from a pressure competent launcher, through a dual seal isolation valve. The seals are hydraulically compressed resulting in radial expansion against the pipe bore. During isolation barrier proving, each seal is tested independently with full pipeline pressure in the direction of the expected pressure differential, proving both seals of the double block isolation are leak-tight. Following successful seal proving, the vented annulus void is then closed and monitored confirming isolation integrity throughout the isolation period.

The line pressure acting against the BISEP pressure head offers a fail-safe feature by providing actuation independent of the hydraulic system. The ejection load resistance is provided by the BISEP deployment head.

Multiple BISEPs can be used to provide mid-line isolation of pipeline sections and the introduction of a bypass line allows sectional isolation to take place without the need to shut down the entire system or affect product flow.

The BISEP can be configured in the Dual Set (DS) configuration which includes an integrated bypass through the launcher, ideally suited to lower pressure applications.

| Specification Title | Specification Description |

|---|---|

|

Size Range

|

3" to 53"

|

|

Pressure Range

|

Up to 153 bar / 2220 psi

|

|

Verification

|

DNV Type Approval: design criteria satisfies the requirements for Pipeline Isolation Plugs to provide dual seal and isolation in accordance with Offshore Standards; DNV-OS-F101 (Submarine Pipeline Systems) and recommended Practices; DNV-RP-F113 (Subsea Pi

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 6 deployment references.

Last Deployment Year