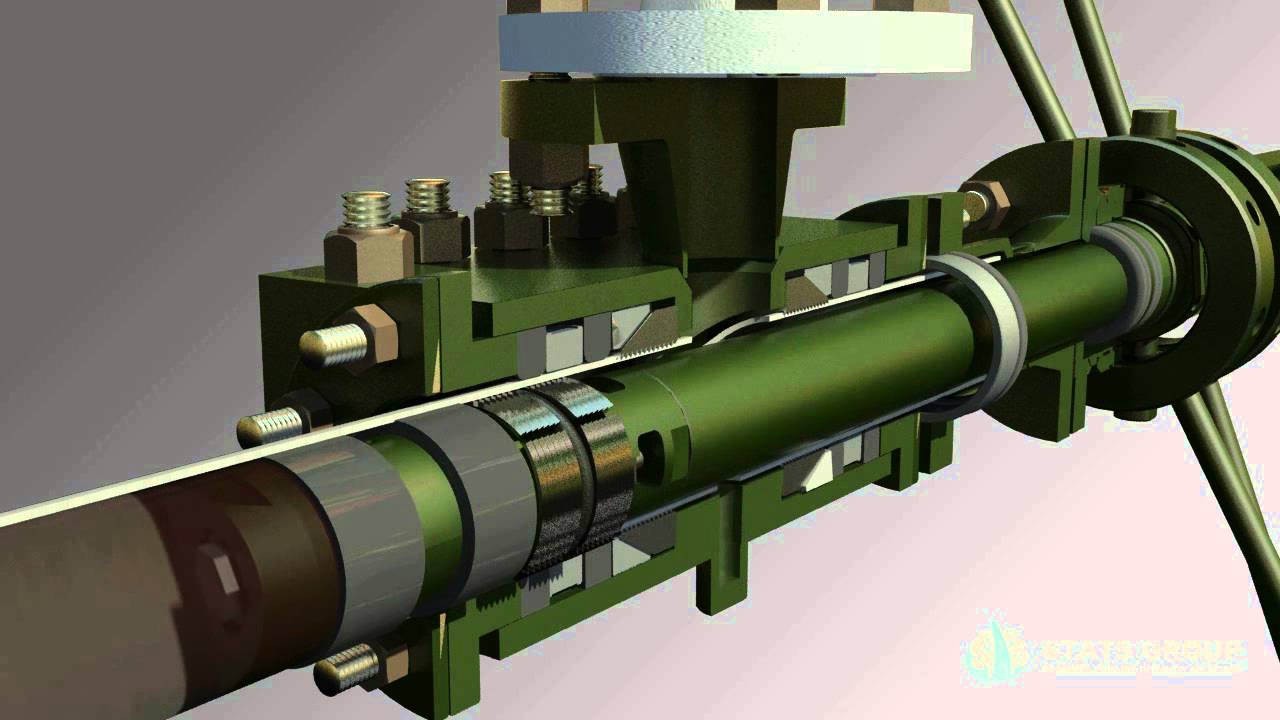

BI-STOP Line Plugging

Small-Bore Line Plugging

The patented BI-STOP™ solution provides a unique temporary line plugging system. BI-STOP addresses challenges with small-bore pipework that have absent or limited isolation facilities. This cost-effective solution enables small-bore pipework to be isolated, cut and if required, terminated with a full-bore valve while the system remains live. BI-STOP allows maintenance or remediation activities to be carried out safely and reliably, eliminating the need for a system shutdown.

Applications

- Provide a temporary isolation to facilitate pipework repair or modification

- Install a system specified full-bore valve where isolation facilities are absent or limited

- Cap and terminate dead leg or redundant pipework

- Provide a permanent or temporary pipework tie-in

| Specification Title | Specification Description |

|---|---|

|

Size range

|

1", 1.5" & 2"

|

|

Pressure range

|

51.1 bar / 741 psi

|

|

ANSI Class

|

300

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 4 deployment references.

Last Deployment Year