AI Plant Expert

Reinventing Predictive Maintenance with AI - A Virtual Expert for Plant Operations

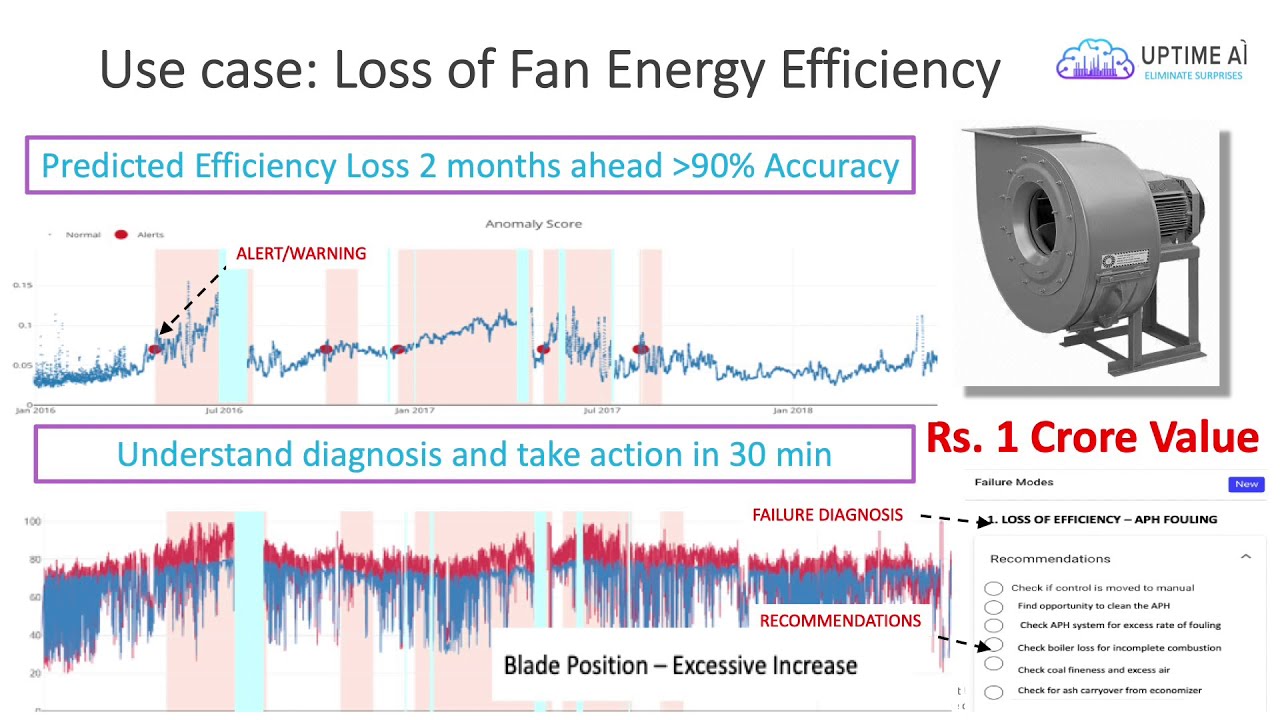

"AI Plant Expert" software is a “Virtual Expert in a Box”, bringing human-like intelligence at scale to minimise failures, inefficiency, and lost productivity in plant operations. With a unique combination of AI, 200+ years of domain knowledge, and self-learning workflows, the solution uses a patented system approach to monitor 100% of the existing equipment, sensor, user feedback, & maintenance data, to continuously learn best practices, predict problems, explain root-cause, and give a prescriptive diagnosis. Results are up to 20% increase in availability, 30% decrease in maintenance costs, 20% increase in productivity with up to 5-10x reduction in false alarms, manual effort, and time to act.

| Specification Title | Specification Description |

|---|---|

|

Accuracy

|

2X-10x reduction in false-alarms, manual effort, and time to act

|

|

Areas of Application

|

Equipment Reliability | Performance | Efficiency

|

|

Connectivity

|

Integrates with historian, CMMS systems, and other 3rd party data lakes

|

|

Cost

|

Significant reduction of monitoring cost/tag so that 100% of the data can be monitored

|

|

Deployment

|

Fast deployment in 2-3 months with limited client time commitments

|

|

Maintenance

|

Up to 30% reduction in maintenance costs with accurate predictions about impending problems

|

|

Monitoring

|

100% plant coverage of rotating and static equipment monitoring with high ROI

|

|

Return on Investment

|

Fast ROI in 6 months with annual subscription pricing and low startup costs

|

|

Services

|

Dedicated customer advocate to support any questions and drive business value

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[8/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 3 deployment references.

Last Deployment Year